Always interested in new technologies and offering increasingly more complete investment casting services, we are able to offer prototype models in wax-infiltrated castform. This material has been tested by the largest American and European precision casters because the material exits the ceramic mould better, leaving hardly any residues.

By using a 2500 Plus sintering laser we are able to produce details on a piece with the maximum size of a paralleliped measuring 330x380x450 mm. For pieces with larger dimensions it is possible to glue the parts of a previously sectioned piece together.

With the mathematical model, this process allows for having one or a small series of wax prototypes that can help develop the final product in a short amount of time.

The level of size precision on a piece created through the sintering process with wax infiltration is quite variable and it is affected by many factors: the size, the shape, the mass and the thinness of the piece.

The process has a standard tolerance of ±0.3% on sizes larger than 100 mm and a surface roughness of 6μ to 9μ (on injection cast prototypes).

The sintering puts a layer of 0.1 mm grain powder down in layers measuring 0.15 mm in thickness.

On inclined surfaces the roughness is greater than it is on vertical surfaces.

With experience we have been able to improve tolerance levels and obtain the following results:

- On widths from 1 mm to 5 mm, a ±0.1mm tolerance; on diameters over 100 mm, a ±0.25% tolerance; on sintering heights over 100 mm, a ±0.5mm tolerance;

- On diameters less than 300 mm we obtain concentricity and roundness equalling ±0.5mm.

These tolerance levels are indicative of the levels we obtain on the parts we build.

Given the fact that it is impossible to control the process, we cannot guarantee the repeatability of size on a series of similar pieces, however it will remain within the tolerance levels indicated above.

A preliminary discussion with the client is necessary in all cases to better define the size and use requirements of the sintering requested.

Sintering classifications:

CLASS A: Prototypes that do not have size requirements and which are for strictly technological use: tests for metallurgic casting, defining casting connections, verifying shrinkage.

CLASSE B: Prototypes for functional testing and processing. In this case, the quotas needing special attention and any tooling modification during processing, must be established carefully. In this case, the piece will be consigned with control certification.

Surface roughness:

1st LEVEL: Surface roughness created by the process (9μ on investment casting);

2nd LEVEL: Polishing the parts that can be accessed easily (6μ on investment casting);

3rd LEVEL: Polishing the entire piece (6μ on investment casting), except for those areas that are not accessible

To better formulate bids, it is preferable to receive a mathematical model of the piece that requires sintering. The sintering process is able to simulate an item in a realistic amount of time. It is very important that the mathematical file is of good quality or that it is a closed volume.

We are able to import all types of files, but we suggest to all of our clients that they consult our software chart to see if their files are compatible with our systems. All of this allows us to provide better quality products and to reduce managing costs.

On request we make models of parts to be sintered such as casting batch connections, we insert special ceramic cores or we can make possible modifications to machine allowances for the investment casting process.

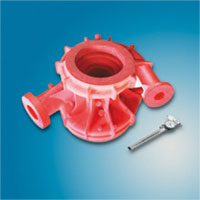

Wax-infiltrated sintering for

Wax-infiltrated sintering for

investment casting

(Ø270[+ flange]x295)

Sintered with a minimum

Sintered with a minimum

thickness equal to 4.2 mm

(size: 600x200x220)

We are also able to supply

prototyped parts in nylon for

small lots or functional testing

We make milled models and

prototypes with 3/4/5 axis C.N.C.

machining, in aluminium, resin

and steel: for wind tunnels, naval

testing laboratories, design etc.

Nylon parts for

Nylon parts for

assembly